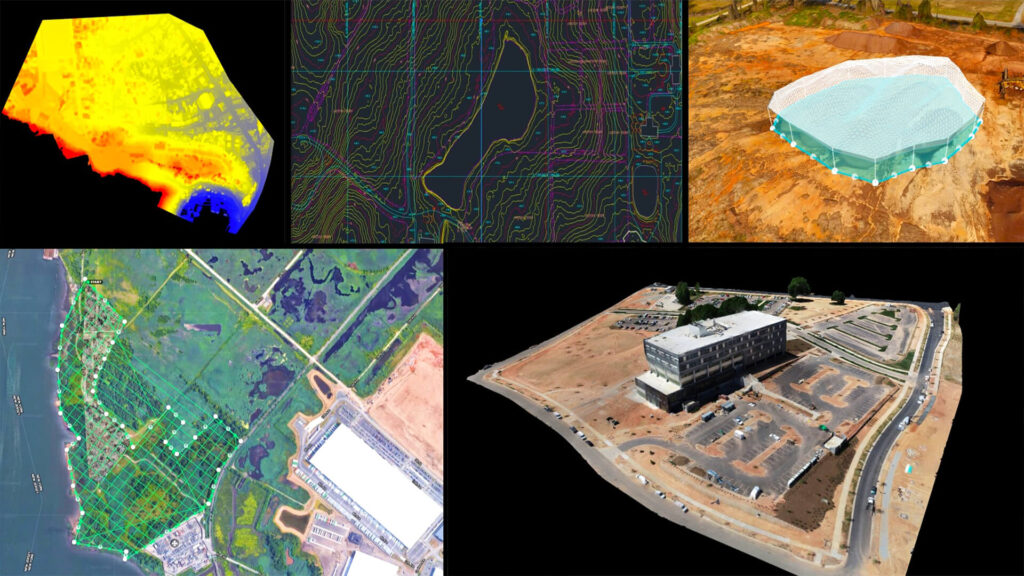

ORTHOMOSAIC MAPS

What is an orthomosaic map, how are they used, and why would you want one?

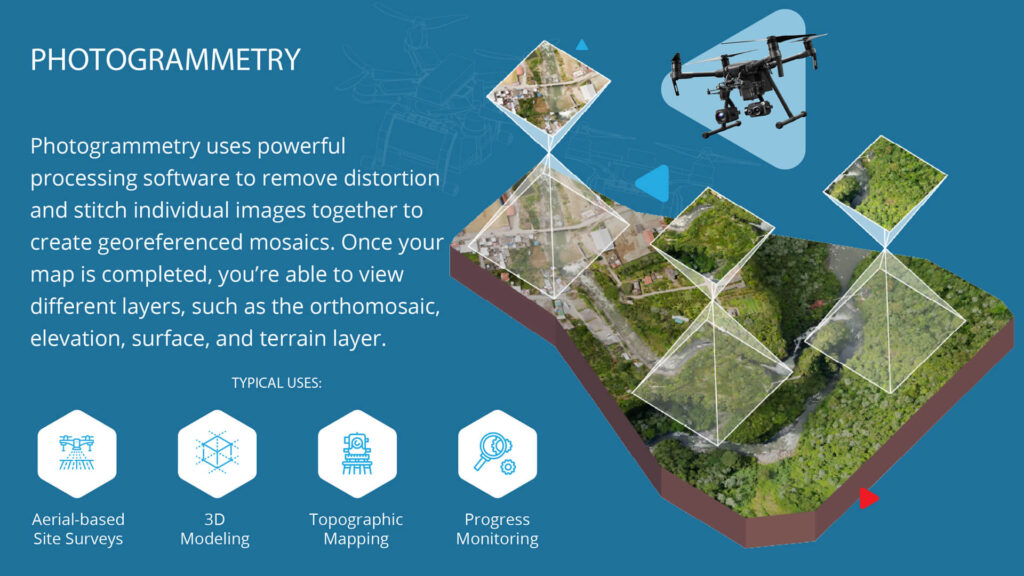

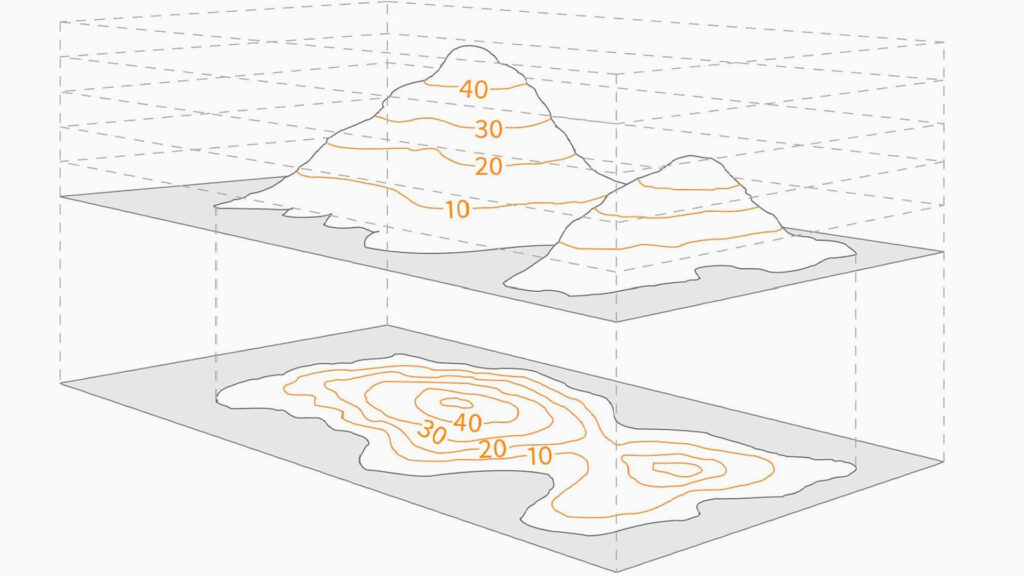

Think of an orthomosaic map as a significantly sharper, higher resolution, and more detailed version of Google Earth. It’s a composite image that captures hundreds (if not thousands) of drone-generated photos and then stitches them together. This process is known as photogrammetry—the science of making reliable measurements using aerial photographs. An orthoimage has been corrected for lens distortion, camera tilt perspective, and topographic relief (the changes in elevation of the earth’s surface and curvature).

These corrected orthophotos carry embedded metadata identifying geo-location, date, altitude, and even camera details, but the key feature is that they have a uniform scale across the image. The critical difference between a standard aerial photo and an orthophoto is the perspective and accuracy. As a result, they can use them to measure accurate distances, from planning and pre-construction to the final inspection; hence, drone mapping can streamline every stage of a construction project.

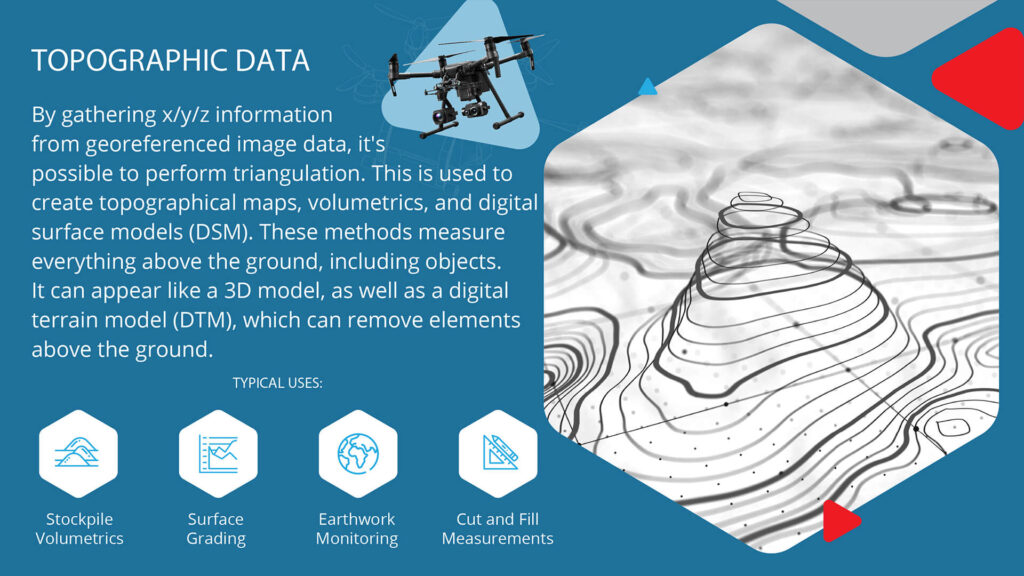

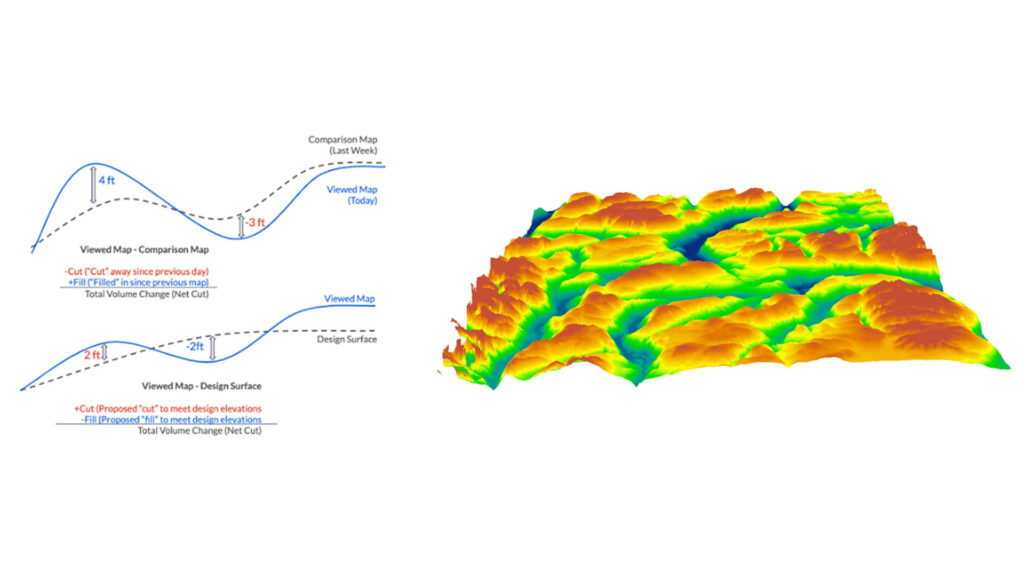

Drone maps help engineering and survey teams quickly achieve accurate topographic data to locate existing site grading, drainage spots, vegetation, and waterways. Construction firms find orthomosaics particularly useful for providing an updated picture of the construction site on a regular basis. In addition, you leverage the accuracy of orthomosaics for precise measurements. Software programs, such as DroneDeploy and Pix4D, allow users to interface directly with the generated map.

You can measure distance, area, and volume, calculate the volume of stockpiles, estimate material costs, and collect other valuable data—all without physically being at the construction site. Orthomosaics are also great for performing aerial inspections to secure equipment and materials. In addition, they can be used to inspect rooftops, solar installations, deteriorating buildings, and much more. Sometimes orthomosaics are even used in court cases, providing updated and accurate imagery needed for legal proceedings.

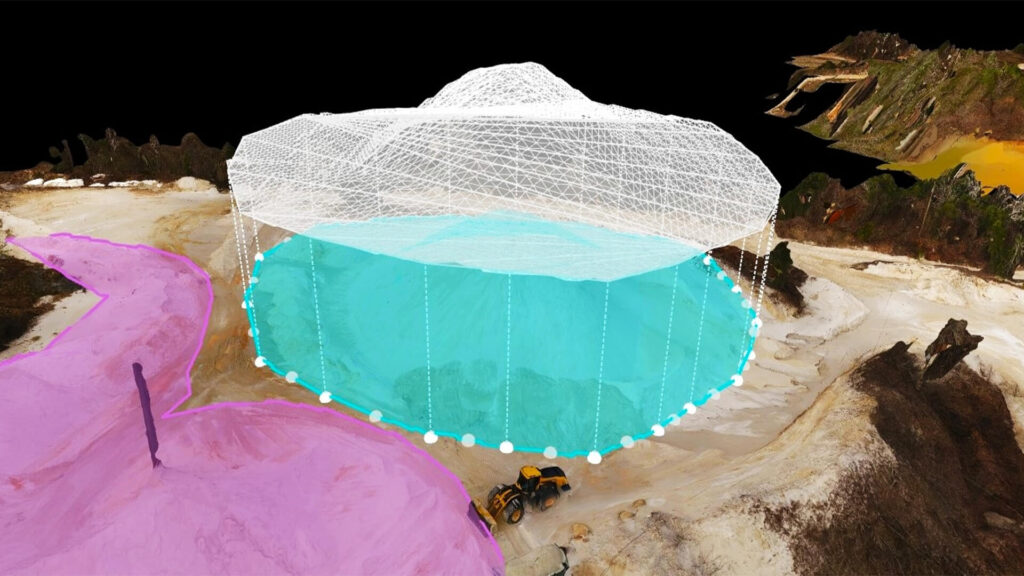

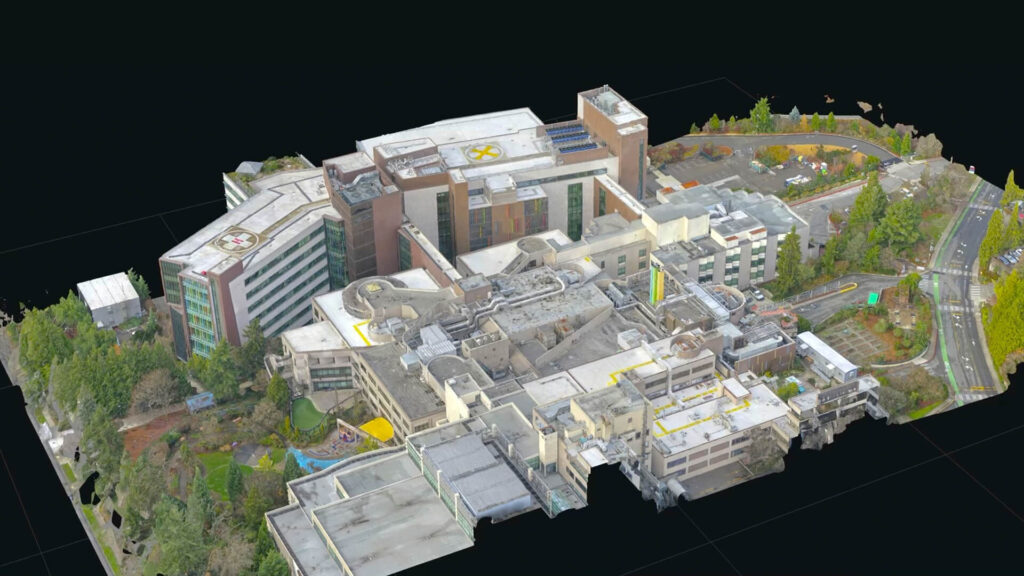

POINT CLOUD AND 3D MODELING

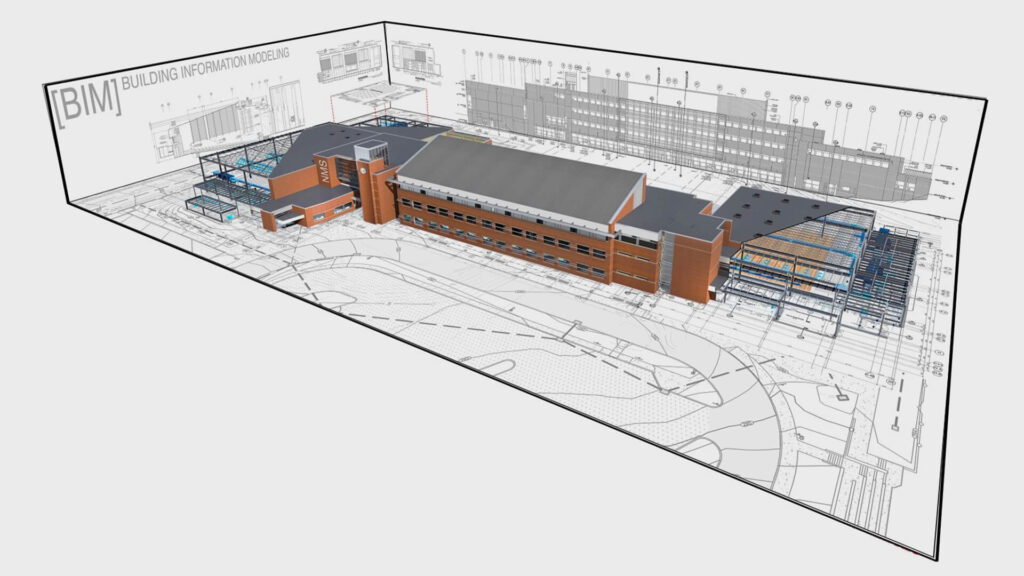

Over the last five years, the commercial construction industry has started incorporating BIM (Building Information Modeling) into both the designing and project management processes. BIM is a project management system allowing real-time 3D information to flow throughout the entire construction process. This enables construction firms and stakeholders to visualize each aspect of the project in a 3D environment, allowing construction project stakeholders to access information in real time.

INTEGRATING DRONE DATA INTO BIM WORKFLOW

Think of BIM as a remote construction site audit that provides visualization of the “as-built” of all components in a building. Integrating drone data into the BIM process takes this CAD design and overlays real-world 3D models ensuring accurate construction from the plans, or “as-built” compared to “design-build.”

CONSTRUCTION SITE PROGRESSION MONITORING

Drones allow you to monitor the evolution of a construction site’s progress via a process known as “construction aerial progress monitoring.” This includes regularly scheduled drone flights to collect project data workflows and document progress and changes, ensuring the scope continues as specified in the agreement.

A few of the critical things that a project manager will look for include observing the various construction trades and establishing their level of completion, identifying and reporting changes, potential or pending change orders, locating the status of stored materials (and, if requested, off-site materials as well), checking for adherence to safety compliance, and much more. After each site visit, a written report, including visual imagery, is created to submit to stakeholders and leadership.

Progress reports are required in contracts and have been part of the construction project process for 100 years. Inspectors perform a “boots-on-the-ground” walk around the site to manually capture images. This can take days or even weeks, making it difficult to fully understand the site’s condition. Also, some sections might not be easily accessible, so the ground-based reports could be missing critical details.

Since drones can quickly photo document even the largest of sites, messages can be completed with much more detail and done much more frequently, giving the project manager more information to make better decisions. These visuals and regular progress reports are also a potent tool for developing stronger relationships with clients, investors, and management. All of these stakeholders can have a very detailed understanding of site progress just by viewing drone images and video.

WHAT DOES THE DRONE OPERATIONS WORKFLOW LOOK LIKE?

A particular workflow exists for conducting aerial drone missions when documenting construction site progress. This workflow process provides a very detailed snapshot of the current conditions on the date we were on site.

One of the first steps is to ask the project manager for a KMZ/KML file of the entire project boundary. This allows us to load the project site into drone flight planning software. The first flight is a pre-planned mission to generate the initial orthomosaic map. Once the KMZ/KML is loaded into the software, we prepare site-specific flight parameters. For example, one of the first steps is to identify the highest obstacle altitude, which, in many cases, determines the flight altitude and how we can acquire the smallest ground sampling distance (GSD). This is the distance between center points of each sample taken of the ground. Since we’re talking about digital photos in drone surveying, each “sample” is a pixel. In simpler terms, the GSD represents the size of one pixel on the ground. Example: 0.5 in/px

Other parameters that need to be considered are the overlap of images (front and side of drone) and direction of flight. Using the flight direction feature allows you to change the order in which your drone flies. Changing the flight path can assist when mapping a narrow shape so that the drone conserves battery life. It can also assist in flying in and out of the wind. Most default flight plans are parallel or cross-hatch pattern flight plans. The difference between the two flight types is quite different.

Standard parallel flights are flown with the camera in a nadir view (the direction pointing directly below a particular location). This type of flight plan is used for a general overview and typically generates 30% fewer images than a cross-hatch flight.

A cross-hatch flight is generally used when there is an anticipation of additional data being needed (i.e., topographical, elevation, surface, 3D point cloud). A cross-hatch creates a netted flight path (a tic-tac-toe pattern) with the gimble/camera angled generally between 25° and 65° to capture oblique angled images. The results are similar to parallel flight orthomosaic but provide incredibly better detail for any 3D deliverables mentioned above.

Once the autonomous ortho flight is complete, we start area-specific flights around 100 to 150 feet (or sometimes just above the tree line), navigating the site and capturing many pictures. Then, we like to get one from each corner and right in front of the site. This is used a lot for planning because it incorporates more straight lines to see the construction site better. Lastly, we repeat the process but are now flying higher up (as long as there aren’t airspace restrictions).

After all image capture is complete, it’s time for the video portion of the workflow. I like to think of the video deliverables from a project management or stakeholders’ perspective. It’s more appealing and almost cinematic to sit in a conference room and view a progress video on a large screen from an aerial perspective. Our video capture is typically around the same angles and perspectives of the imaging. So, the last video capture we create is a slow “point-of-interest” orbit at an altitude and angle that will provide a detailed view of the focal point and capture the surrounding conditions of the job site.

Sometimes (depending on the size of the area), we will capture a 360° pan of the surrounding properties. These are primarily used for marketing. If the site is small enough, doing top-down videos is possible. Typically, on the last flight, when the project has been completed, it’s an excellent opportunity to create video and image assets for marketing purposes to showcase the project.

HOW DO STAKEHOLDERS BENEFIT?

Construction professionals often spend 35% of their time on non-optimal activities. This arises from poor communication due to teams working in silos and not sharing common data platforms, and can lead to many hours spent each week managing disputes between project stakeholders. Additionally, it often leads to more time spent assessing mistakes that require rework. The key is setting up standards and checkpoints to keep the data sharing constant and making transparency the norm for all worksite communication.

Construction projects are extensive, sophisticated operations involving dozens of parties, from clients, investors, contractors, and workers. Effective communication is crucial for reducing mistakes and finishing the job according to the schedule. One of the biggest reasons our clients use drone maps is how easy, quick, and efficient it is to share and collaborate on the data. They often put the map on a projector during meetings to point out specific areas and plan for the upcoming phases. Often, stakeholders are located across the country or even overseas, so visiting on-site for updates is impractical. Drone maps allow them to keep tabs on the project and visualize the work being done.

The savings that construction firms can expect from drone mapping technologies can be grouped into two major categories:

- Increasing profit margins

- Reducing opportunity costs

Here are just some of benefits of drone mapping:

- Improve real-time monitoring

- Improve workflow efficiency

- Enable faster tracking of assets

- Communicate progress faster

- Catch conflicts sooner

- Identify hazards and enhance safety

- Mitigate dirty, dangerous, and dull jobs

- Identify trends — good or bad

Whether it’s subcontractors, clients, investors, workers, project management, or any other project stakeholder, drone mapping enables everyone on the construction project to work together better, faster, and more efficiently.

Frank Segarra

Frank Segarra is the Senior Vice President of Sales at Volatus Aerospace. He has over 30 years of IT, telecommunications and aviation industry experience and was a US Navy aircraft carrier airman specializing in Avionics Engineering. As a thought leader in drone technology, Frank was invited to be a founding member and CompTIA Drone Advisory Council. and is on the Board of Advisors for the PA Drone Association.